Waste to want: Innovative solutions to food waste

Single use, disposable, throwaway products have made, and continue to make, life convenient and affordable. Yet, nearly 70 years since Life magazine was credited with coining the term ‘throwaway living’ we feel and see that ‘away’ creeping closer and closer. Unless an item can be reused or recycled then it is heading to a landfill site; and despite our best efforts this can seem an insurmountable problem.

This is especially true with food, where many of us fall short of fully utilising the principles of nose-to-tail or root-to-stem eating. In fact around 17% of total food production is wasted. Large amounts of food waste create large amounts of planet-warming methane gas alongside the significant amount of energy required to transport the waste to landfill or composting facilities. In total, food waste produces 6.7% of global greenhouse gas emissions as it decays, adding to the challenges facing the world whilst also representing a huge loss in useful and resource-intensive material.

Fortunately, innovators are stepping in to turn food waste into useful material, and transform that useful material into second-use products.

One such visionary business is Waister AS, based in Norway. It has developed and patented a system capable of transforming raw food waste into a dry, storable material to be used as a biogas booster for the generation of energy. Without the weight of water in the product, the equivalent of ten waste lorries full of wet waste can be transported in just one. The technology behind the system can easily be scaled down, making it suitable for commercial kitchens or other small scale food waste producers. This allows smaller waste streams to be captured at source and transformed into a useful material. The professional kitchens benefit as they don’t have to store and dispose of large amounts of waste, and the planet benefits as that waste is directed into useful applications. Often the best innovations (and the best patent applications) solve more than one problem at a time.

One drawback of producing energy from waste is that useful complex materials are broken down and lost. But harnessing these complex materials from waste takes a lot of effort, involving a first step of getting hold of just one component from the mixture.

Take eggs for example. In the UK alone, 202 eggs were consumed per person every year from 2004 to 2021. Multiply this globally, and that adds up to a lot of egg shells being composted or added to landfill.

One Norwegian company, Biovotec AS has developed and patented a method and apparatus capable of separating egg shell components from the egg membranes. The technology can be installed in line with industrial egg processing, which will enable the harvesting of the useful egg membrane from a waste stream at source.

This technology has facilitated the production by Biovotec of a patented biocompatible film formed from egg shell membrane. The film harnesses the healing properties of the membrane, forming a material that can be used as a wound dressing, or as implantable material that enhances wound healing and disintegrates after use.

Through a combination of technologies a small step has been taken towards chiselling down the resulting waste mountain. This is an excellent example of how there is rarely just one patentable invention behind a commercial product.

Similarly, UK based company Bio-Bean has developed processes that separate materials from coffee grounds to provide solid biomass fuels, natural compounds for use in food and drink, and recycled components for industry.

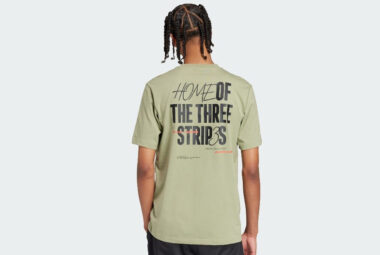

One surprising coffee waste product is a yarn made with coffee residue. This patent protected material prepared by Singtex is formulated by blending baked coffee grounds with a polymer and spinning the mixture into yarns. The presence of the coffee grounds in the mixture imparts odour, heat control, and UV protection to the material, reducing or eliminating the need for the synthetic additives required to give pure polymer fabrics the same qualities. Using similar techniques the same innovators have even produced a waterproof bio-membrane using 26% coffee oil for use in wind proof and waterproof clothing.

Slowly, waste is working its way back into our lives, but this time for the better. The global patent system is being used to protect this innovation, enabling a cleaner and greener future for all of us.

If you would like to discuss your innovative waste management or recycling idea, please get in touch with the author or your usual Barker Brettell attorney.